High Temperature Diesel Exhaust Filter

Global Mining Supplies specialises in the provision of diesel exhaust management products and services. Specifically, long life, high temperature, Diesel Particulate Filters that reduce the exposure of underground mining personnel to diesel particulate matter.

Custom made to suit any exhaust system

Our filters are currently available for:

- Jug-A-0 Loaders

- Eimco Loaders

- Coal Tram Loaders

- PJB Mine Cruisers

- Driftrunner Man Transporters

- Industrea Graders

- Shearer Transporters

If you are using other engine packages, please contact us directly, we would be happy to develop the appropriate filter to meet your specific requirements.

Our Filter Benefits

- Provide significantly greater operational time than the current paper and cellulose based filters, giving cost effective filtration for customers.

- Reduce down time on machines, resulting from extended life.

- The FST filter medium does not swell or choke off when exposed to water, ensuring greater filter life and reducing the impact of the wet scrubber machines.

- Provide greater operational time between changeout of the filters, allowing customers to change out on a weekly service, or be more targeted in their change out regime.

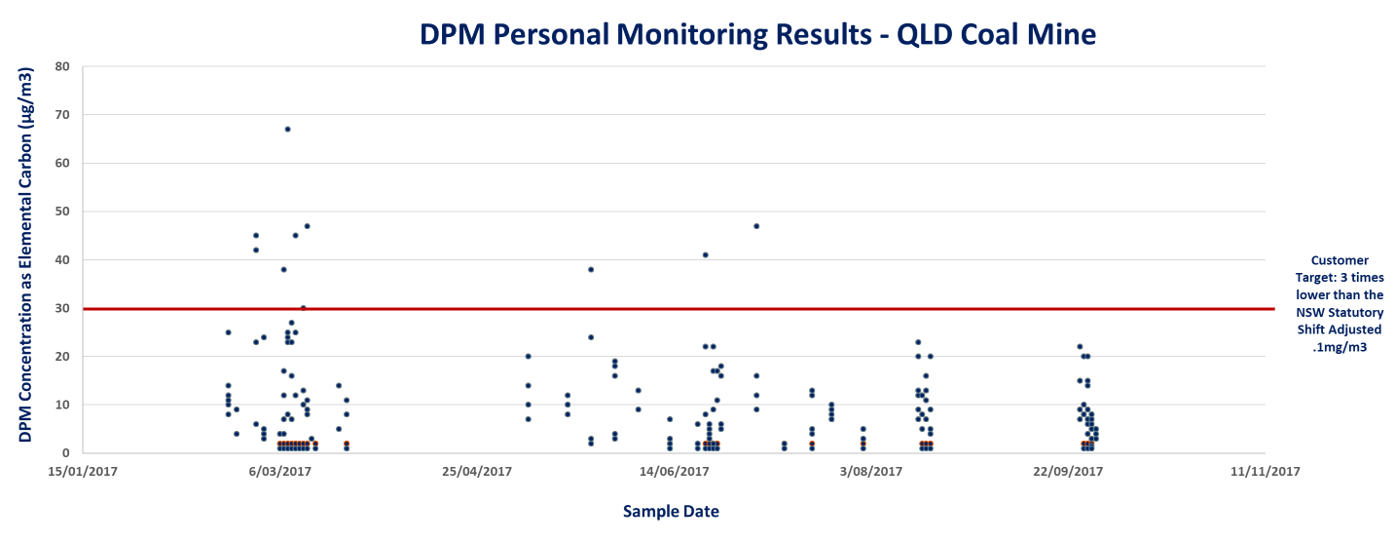

- Reduce personal exposure and environmental impact associated with filter element disposal. Two of our customers reported they have reduced and maintained DPM exposure levels to less than 1/2 the personnel exposure target limit while using the GMS filter.

- Enable reduced disposal costs at landfill operations which is a cost saving to mining companies.

- Significantly reduce freight and manual handling costs.

- Increase diesel machinery operating hours and availability.

- Reduce the exposure of people to contaminated filters and the environmental impact by 75%. A current customer was able to reduce their number of waste bins per year from 84 to 17 by using the GMS filters.

- Reduce the time required by underground operators and/or fitters to change out filters, with one customer saving over $500,000 in contractor wages by using GMS's filters with an increased life.

Click to Enlarge

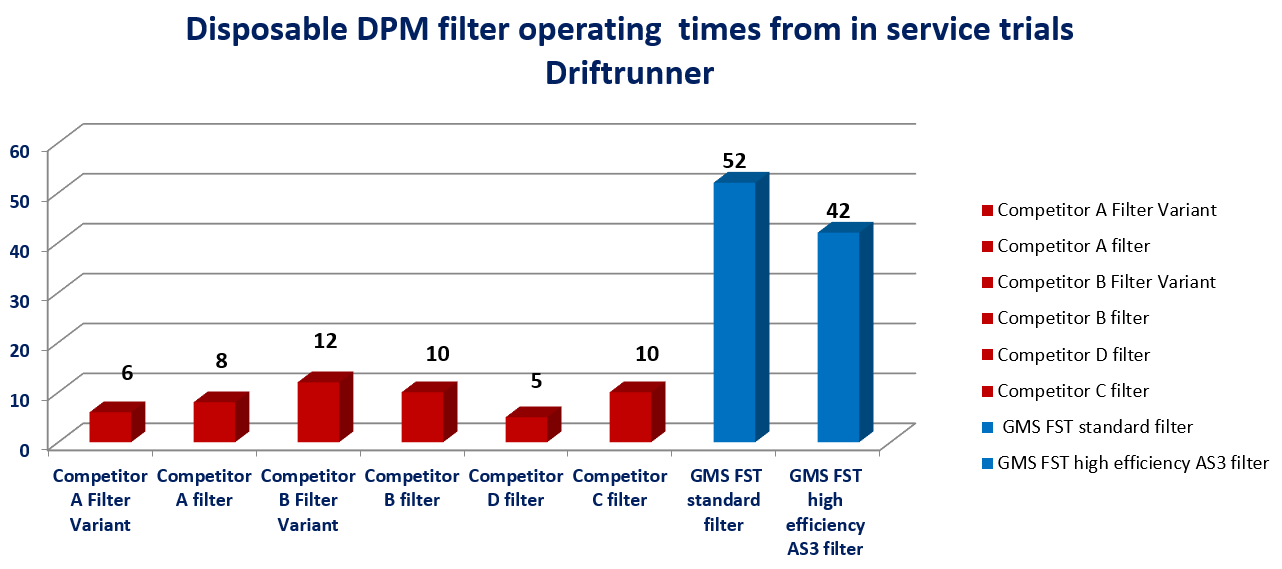

Filter Life Comparison Results

See comparison results (below) of controlled in-service trials conducted at an underground coal mine, with the same diesel powered machine operating, under the same duty cycle.

Click to Enlarge

High Temperature Filters

Global Mining Supplies filters meet Australian standard AS3584:2. They have been tested and approved by the TestSafe and MSHA for use in underground coal mines in the USA and Australia to the following levels:

- Filter medium rated to > 700° C

- Filter assembly including gasket material, potting mix rated to > 400° C

- The above temperatures pertain to both clean and used filters.